ATG

WF RANGE – MEDIUM PRESSURE

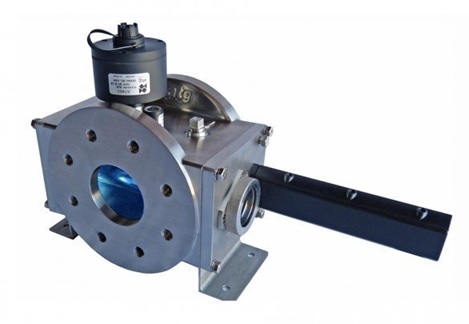

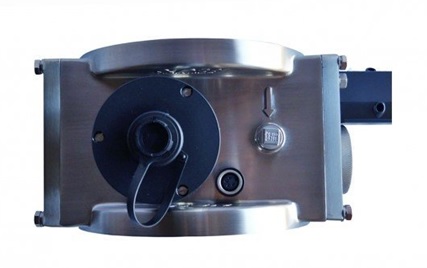

Launched in October 2015, the Wafer (WF) range is the next generation of medium pressure UV systems. It is ideal for drinking water and aquatic applications. The WF range is ATG Evoqua’s flagship medium pressure UV system.

The WF design, also known as the Wafer due to its unique UV chamber design, will offer the most compact UV system available in the market today. At around a third of the size of comparative UV systems and with significantly reduced maintenance space, the WF series promises to offer easy to install and retrofit solutions that will fit the tightest of plant rooms.

PERFORMANCE ADVANTAGES

- 9,000 hour lamp life

- High disinfection efficiency (1 to 5 log)

- Chemical free (green disinfection solution)

- Automatic power stepping 100% – 30% power

- Hydraulically optimised low head-loss design

- Validated doses from 12 mj/cm2 RED to 120 mj/cm2 RED or more

INSTALLATION ADVANTAGES

- World’s most compact UV System

- Easy to install, operate & maintain

- Horizontal and vertical installation options

- Suitable for both new builds and retrofits

- Multiple flange size, type and mounting options

- Closed system design installs directly into pipe work

- Options for modular installations to increase capacity

- Up to 50 meter cable distance from LCP to UV chamber

- Modbus / Profibus / ICSS / BMS integration available

OPERATIONAL BENEFIT

- Simple to install and operate

- Separated lamp and wiper access

- TWISTLOKTM lamp design for enhanced safety

- Significantly reduces maintenance requirements

- Single sided lamp

- Robust, chemical free automatic wiper system

- Lamp changes without removing wiper motor

- Dry mounted UV monitors and temperature probes

ECL RANGE – MEDIUM PRESSURE UV

The ATG Evoqua ECL series provide the very latest in medium pressure UV lamp technology and in-line UV chamber design. Offering increased treatment capacity and flexibility for the environmentally friendly process of UV disinfection, the ECL series provide solutions for a range of applications including drinking water, industrial process water, food & beverages, and aquatics.

Featuring both single lamp and multi lamp configurations and using a range of medium pressure UV lamps, the specially designed in-line UV reactors provide optimum flow distribution and hydraulic performance. The ECL range offers a state-of-the-art solution for a wide variety of water treatment applications, treating capacities of 1.0 m3/hr to more than 5,000 m3/hr in a single, high output, low footprint UV system.

PERFORMANCE ADVANTAGES

- 9,000 hour lamp life

- High disinfection efficiency (1 to 5 log)

- Hydraulically optimized low head-loss design

- Automatic power stepping 100% – 50% power

- High capacity treatment up to 1,200 m3/hr

- 1.3 kW, 1.5 kW, 2.0 kW, 2.5 kW, 3.0 kW UV lamps

- Single lamp, 2 and 4 multi-lamp configurations

- Chemical free (green disinfection solution)

- Independent 3rd party validated performance

INSTALLATION ADVANTAGES

- Ultra-compact and easy to install

- Suitable for both new builds and retrofits

- Horizontal and vertical installation options

- Significantly reduced footprint requirement

- Multiple flange size, type and mounting options

- Can be installed directly against walls / structures

- Closed system design installs directly into pipe work

- Up to 50 meter cable distance from LCP to UV chamber

- Modbus / Profibus / ICSS / BMS integration available

OPERATIONAL BENEFIT

- Simple to install and operate

- Separated lamp and wiper access

- Single sided maintenance / access

- Significantly reduces maintenance requirements

- Robust, chemical free automatic wiper system

- Lamp changes without removing wiper motor

- Dry mounted UV monitors and temperature probes

- Wiper rings can be replaced without removing wiping carriage from chamber