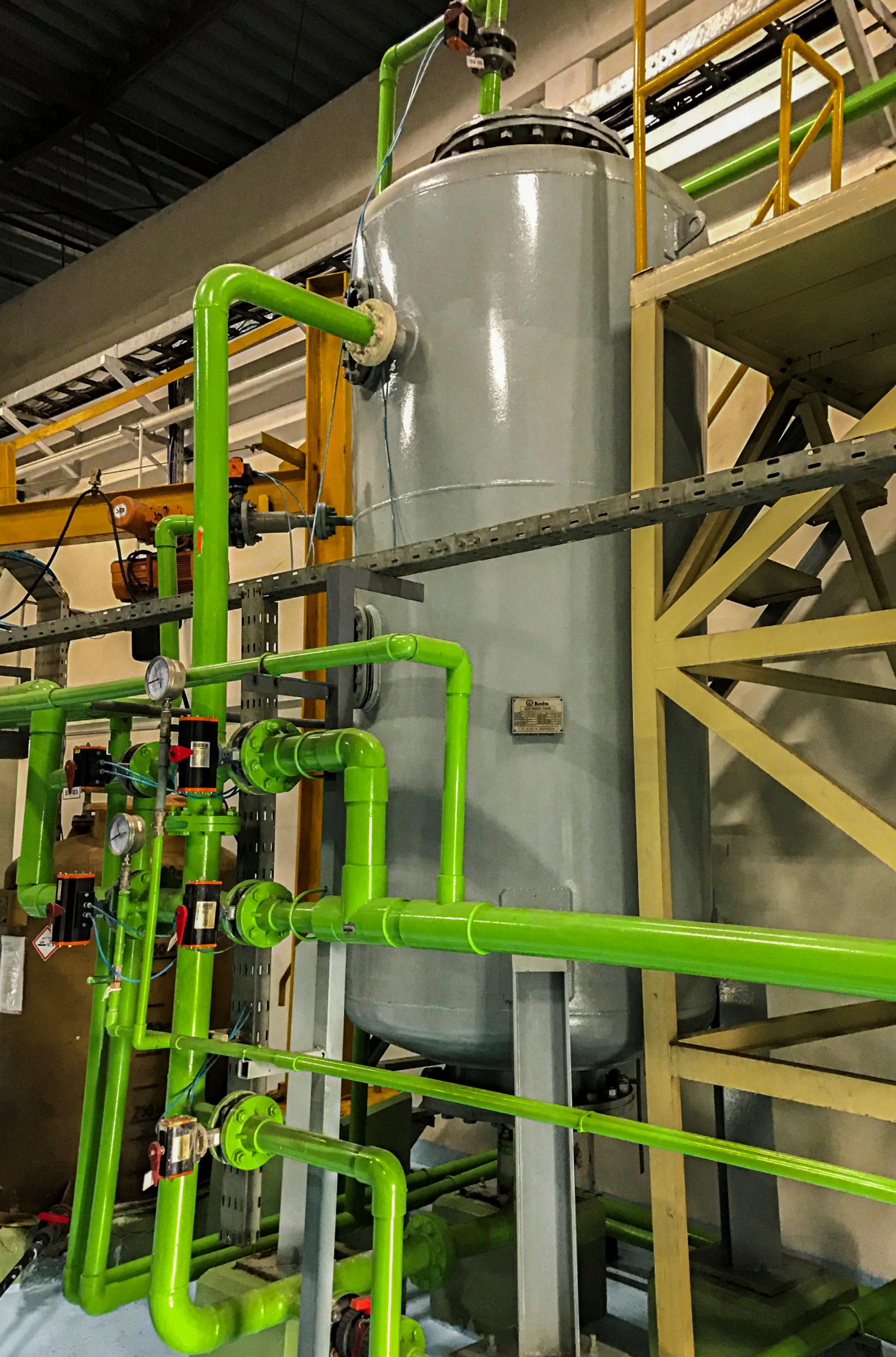

ION EXCHANGE SYSTEM

HUI Ion Exchange System comes with semi manual and fully automatic system. Allow us to monitor its performance and remotely control water quality. It is skid mounted, compact and efficient in operations. We offer standard equipment specifications and high specification with explosion proof zone 0 complete compliance standards as options. HUI Ion Exchange system is installed directly on the main water supply, but it can also be used as post-treatment for reverse osmosis water (polishing).

SOFTENERS – REMOVAL OF CALCIUM (Ca) & MAGNESIUM (Mg)

Precipitation softening processes are used to reduce raw water hardness, alkalinity, silica and other constituents. This helpsprepare water for direct use as cooling tower makeup or as a first-stage treatment followed by ion exchange for boiler makeup or process use.

Water is considered ‘hard’ when it has excessive levels of calcium and magnesium dissolved in it. Hard water can lead to the following water problems:

- Scale build-up in pipes, resulting in decreased flow rates

- Scale build-up on heating and cooling systems, leading to increased electricity costs and breakdowns

- White film on glass surfaces and staining on Water taps

- Increased laundry costs due to hard water reacting with soap and laundry detergents

The Water Softening Plants are designed to produce treated Water to suit for various applications. Treated Water is of consistency quality with low residual hardness throughout the service cycle. The high synthetic resin is used to exchange Sodium ion with hardness forming Calcium and Magnesium ions. After producing desired output, the resin is regenerated with (NaCI) Sodium Chloride solution after which unit is again ready to deliver next batch. The Water Softening Plant units are available with different models. The difference between these models is in the capacity of the resin used for each model. These units are easy to operate and maintenance free. These models are available to produce various capacities up to 200 Cu meters per hour maximum.

PROCESS

Water softening methods mainly rely on the removal of Ca2+ and Mg2+ from a solution or the sequestration of these ions, i.e. binding them to a molecule that removes their ability to form scale or interfere with soaps. Removal is achieved by ion exchange and by precipitation methods. Mineral tank and the brine tank are the main constituents of the water softening system. The water softening system consists of a mineral tank and a brine tank. The mineral tank and the water supply pipe is connected due to which water passes through the tank before it can be used. Mineral tank consist of negatively charged beads or resins that attracts positively charged calcium and magnesium.

The surface of the resin gets coated with the calcium and magnesium minerals. The resin is cleared by flushing a strong sodium (salt) solution held in the brine tank. The sodium ions are powerful and they easily overpower the calcium and magnesium ions and drive them off of the resins which is later drained out of the unit.

APPLICATION

- Boiler feed

- Cooling tower make-up

- Air conditioning plant

- Textile processing

- Beverage production

- Hospitals, hotels, laundries and etc.

- Food processing

- Chemical & textile

- Water power plants

- Ice plant

- Dyeing processes

- Pharmaceutical industries

- Product finishing

HUI design and manufacture very efficient water softeners that are effective in reducing the hardness of the water. They help in producing zero soft water by highly acidic cation exchanger which removes calcium and magnesium ions from the waterr. Our water softener plant is portable and easy to move from one place to another. It also involves less effort in terms of installation and maintenance. As one of the leading drinking water softening plant manufacturers based in India, we make our products available to our customer’s at the most affordable price range.

STANDARD SPECIFICATION

| Filter Type | FLAX-S-50 | FLAX-S-75 | FLAX-S-125 | FLAX-S-200 | FLAX-S-325 |

| Flow Rate (m3/day) | 24 | 36 | 60 | 100 | 156 |

| Resin Volume (ltr) | 50 | 75 | 125 | 200 | 325 |

Specification above are based on Raw Water Parameter as follow :

Turbidity : < 1 NTU

Free Chlorine : ≤ 0.1 ppm

TDS : ≤ 150 ppm

Total Hardness : ≤ 90 ppm as CaCO3

For custom size and specification, please don’t hesitate to contact us.

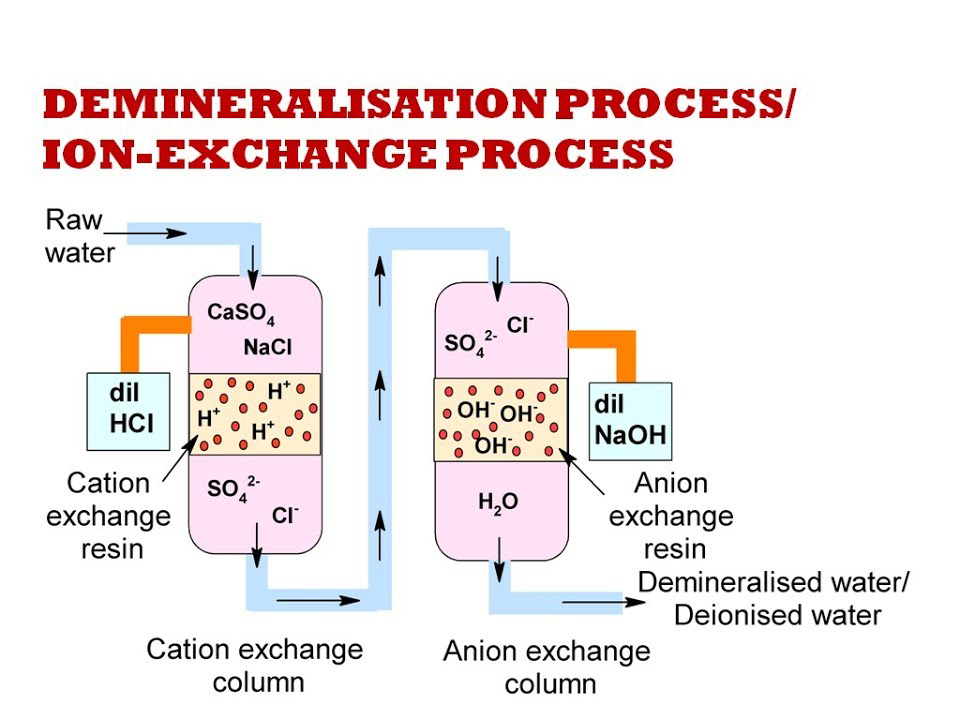

DEMINERALIZATION PLANT

Demineralization (Demin) is the process of removing mineral salts from water by using the ion exchange concept. Result of this system is Demineralized Water also known as Deionized Water. Demin plants consist of two pressure vessels that containing cation resin and anion resin. Typically, Demin plants produce TDS < 20 ppm at outlet, for TDS < 1 ppm consider to add Mixed Bed system.

Ion-Exchange Process

Ion-Exchange is a rapid and reversible process in which impurity ions present in the Water are replaced by ions released by an ion-exchange resin. The impurity ions are taken up by the resin, which must be periodically regenerated to restore it to the original ionic form. Positively-charged ions are called cations and are usually metals, negatively-charged ions are called anions and are usually non-metals

STANDARD SPECIFICATION

| Filter Type | FLAX-DM-15 | FLAX-DM-20 | FLAX-DM-30 | FLAX-DM-40 | FLAX-DM-50 |

| Flow Rate (m3/day) | 30 | 48 | 72 | 96 | 120 |

| Cation Resin (ltr) | 125 | 200 | 275 | 375 | 475 |

| Anion Resin (ltr) | 350 | 575 | 900 | 1150 | 1450 |

Specification above are based on Raw Water Parameter as follow :

Turbidity : < 1 NTU

Free Chlorine : ≤ 0.1 ppm

TDS : ≤ 150 ppm

Silica : ≤ 10 ppm

For custom size and specification, please don’t hesitate to contact us.

Mixed Bed Polishing Plants

HUI design and build Mixed Bed (MB) polishing plants after Reverse Osmosis or Demin plants to produce DI (Deionized) water < 1 uS/cm. Ultra-pure water (resistivity >15 MΩ) system also available on request.

Design Data

Raw Water Conductivity : Max. 10 uS/cm

DI water outlet : < 1 uS/cm

Silica outlet : < 0.02 ppm

System Recovery : 96 -99 %

Our Ion Exchange plants include:

- Feed pump (optional)

- Pressure Vessel

- Conductivity sensor

- Valves and fittings (manual or automatic)

- Acid regeneration system

- Caustic regeneration system

- PLC Controlling system (for automatic)