WASTE WATER TREATMENT SYSTEM

HUI specialises in designing, manufacturing and commissioning of package plants for wastewater treatment. Waste Water Treatment (WWT) process is removing contaminants from waste water or sewage and convert it into an effluent that can be returned to the water cycle with acceptable impact on the environment. The treatment process takes place in a Waste Water Treatment Plant (WWTP) and it also refers to as Water Resource Recovery Facility (WRRF) or Sewage Treatment Plant (STP) in the case of domestic wastewater. Pollutants in waste water are removed, converted or broken down during the treatment process.

Waste water can be upgraded to process, or portable water standards. HUI assists municipalities and industries to reduce their reliance on increasingly undependable natural water sources and produce environmentally safe effluent and solid waste that can be reused for a variety of applications.

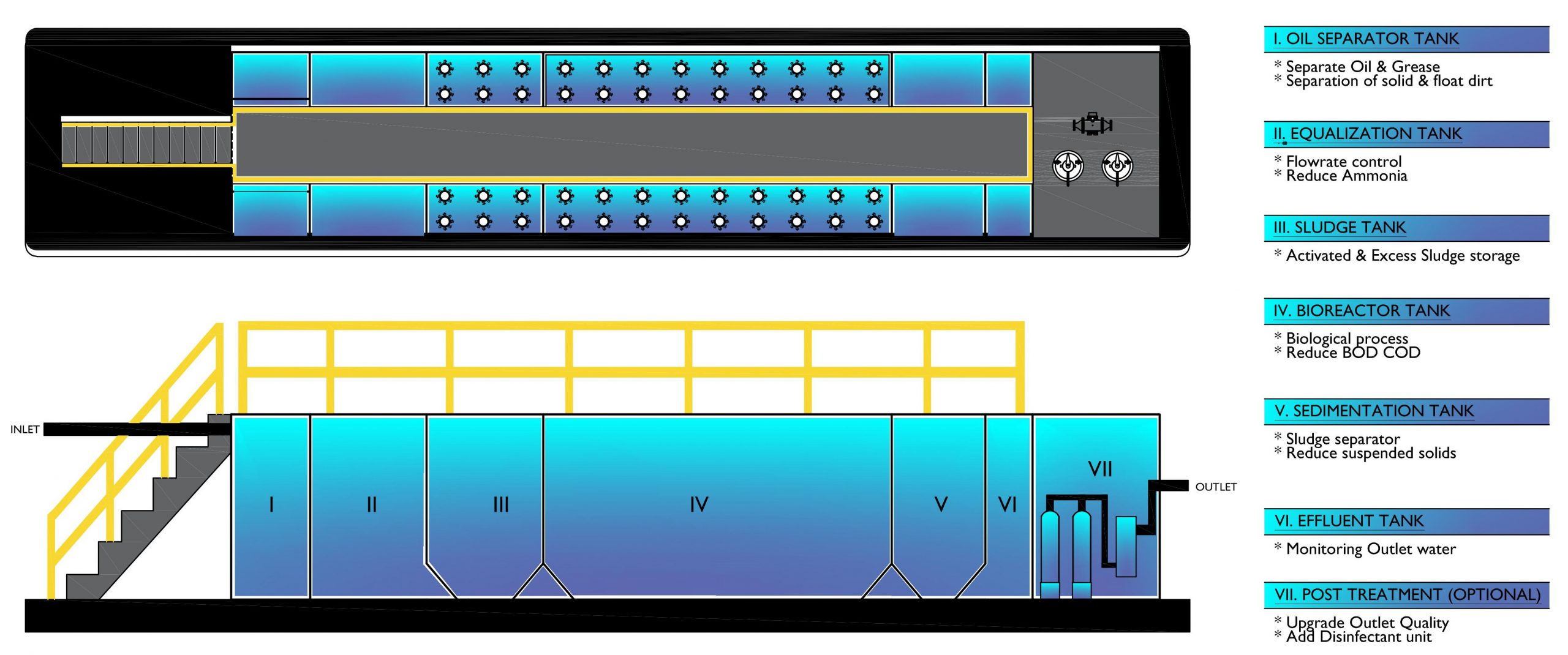

HUI industrial water treatment plant offers smaller foot print, faster retention time and environmentally friendly. Fully containerised waste water treatment plant package is available to meet client requirement.

Advance technologies and processes for industrial waste water treatment applied in HUI waste water system provide solution for your industrial wastewater treatment requirements.

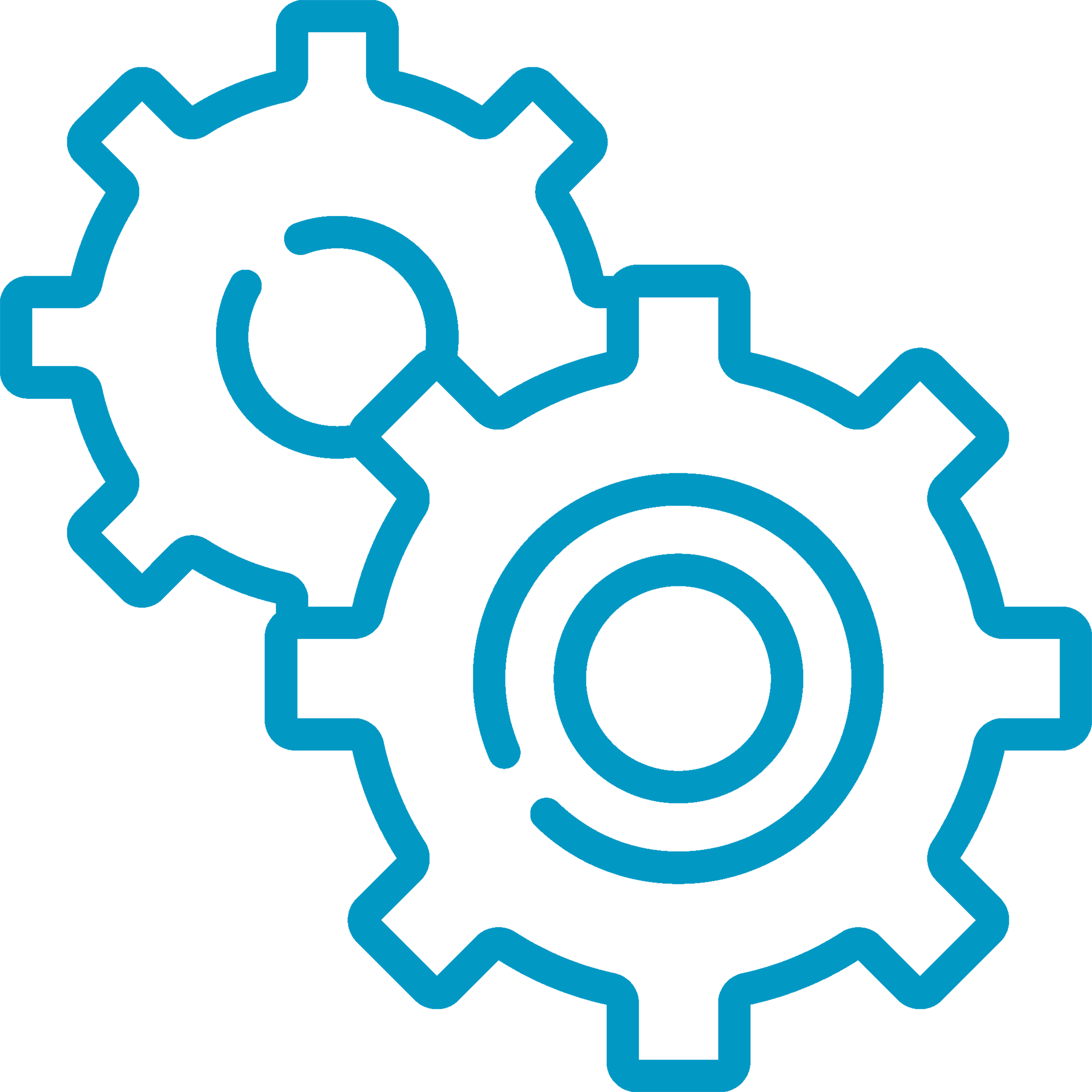

PROCESS

- Biological: Aerobic and Anaerobic process, Moving Bed Biofilm Reactor, Membrane Bioreactor

- Disinfection: Chemical, Ozone, Ultraviolet

- Clarification: Clarifier Tank

- Oil and Water Separation: Dissolve Air Flotation

- Ion Exchange: Anion Cation Resin

- Membrane Separation: Reverse Osmosys, Ultrafiltration, Nanofiltration

- Sludge Treatment and Handling: Filter Press, Centrifuge.

BENEFIT

- Fast lead time in design engineering and fabrication

- Compact portable unit ideal for remote locations

- Pre-assembled and factory-acceptance-tested in Jakarta

- Lower maintenance and simple operation

- Full plug-and-play methodology

- Cost-effective alternative to in-ground treatment plants

- Transportable to practically anywhere

HUI DISSOLVE AIR FLOTATION (DAF) SYSTEM

Multi-stage treatment process

Screening

Oil Separation

Equalization

Sludge Activation (Unaerobic)

Bioreactor (Aerobic)

Sedimentation

Effluent Control

Disinfection

ADVANTAGES

- Smaller foot print

- Faster retention process

- Custom design

Systems are designed to handle a range of influent flows and consistently reduce TSS and BOD to <20mg/L.

The application is for developments like housing estate, hospitals, hotels, and rural communities that are required to treat wastewater to levels suitable for discharge.

Process

Firstly waste water enters WWTP unit passing through a bar screen for large solids removal. Then the oil separator separates oil and suspends solids from water so that it can be skimmed away. In the equalization tank, water is retained to create a homogenous mixture prior to treatment by micro bubbles. Then, the process continues to anaerobic process in the sludge activation tank. It is believed that the function of the process is to remove organic pollution in wastewater, slurries and sludge are removed. The next biological process uses oxygen to break down organic contaminants and other pollutants such as nitrogen and phosphorous. It can also reduces ammonia, COD and BOD. After sufficient contact time in the aeration chamber, water flows into the clarifier and solids settle in the hopper-bottom tank. Then, solids are recirculated through the system or withdrawn as needed. Finally, clean water flows through the clarifier into the clear well where it is re-pressurized and passed through the tertiary filters and disinfection system.